Page 29 - PEN Ebook May 2021

P. 29

Power Supply Power Supply

desorption of ions in the electrolyte contained

between its electrodes.

These processes are much quicker than the

chemical reactions that would be found in bat-

tery charging. With supercapacitors having a

low internal resistance, the device can be fully

charged within a few seconds, whereas a lithium

coin cell used in a secondary battery application

could take anywhere betweenfrom ten minutes

to several hours to be fully charged due to far

higher resistance. Also, there is no theoretical

limit to cycle life, whereas a lithium-ion second-

ary cell has a finite lifetime of approximately 500

cycles.

Figure 1: The internal workings of a supercapacitor.

Recent advancements in carbon-based materi-

SUPERCAPACITOR als mean porous electrodes can be designed to

FUNDAMENTALS have a large surface area which results in a high

Firstly, in terms of how they work, many super- capacitance value and small external dimensions.

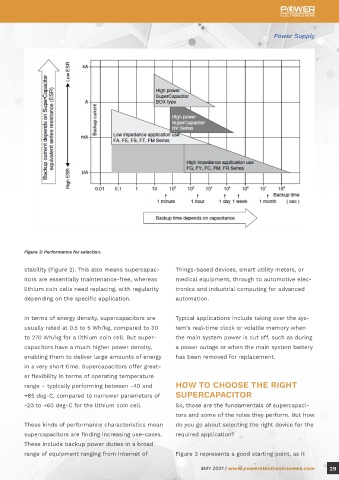

capacitors use what is known as the Electric Supercapacitor construction using aqueous elec- Figure 3: Performance for selection.

Double-Layer Capacitor (EDLC) layout featuring trolytes are inherently conductive, come with a

two electrodes that are often coated in a car- low environmental impact and offer non-flam- stability (Figure 2). This also means supercapac- Things-based devices, smart utility meters, or

bon-based porous material, andmaterial and mable characteristics, and this yields excellent itors are essentially maintenance-free, whereas medical equipment, through to automotive elec-

separated by an electrolyte that is itself divided performance and strong safety credentials. lithium coin cells need replacing, with regularity tronics and industrial computing for advanced

by a membrane (Figure 1). While batteries rely on depending on the specific application. automation.

a chemical reaction, the supercapacitor is differ- Typically speaking, they also have greater re-

ent in that it stores and releases energy very rap- sistance to moisture absorption than organic In terms of energy density, supercapacitors are Typical applications include taking over the sys-

idly through a process of physical adsorption and compounds, resulting in a longer life with better usually rated at 0.5 to 5 Wh/kg, compared to 30 tem’s real-time clock or volatile memory when

to 270 Wh/kg for a lithium coin cell. But super- the main system power is cut off, such as during

capacitors have a much higher power density, a power outage or when the main system battery

enabling them to deliver large amounts of energy has been removed for replacement.

in a very short time. Supercapacitors offer great-

er flexibility in terms of operating temperature

range – typically performing between -40 and HOW TO CHOOSE THE RIGHT

+85 deg-C, compared to narrower parameters of SUPERCAPACITOR

-20 to +60 deg-C for the lithium coin cell. So, those are the fundamentals of supercapaci-

tors and some of the roles they perform. But how

These kinds of performance characteristics mean do you go about selecting the right device for the

supercapacitors are finding increasing use-cases. required application?

These include backup power duties in a broad

Figure 2: High-Reliability Design: Cell Construction Differences between aqueous and organic-based electrolytes. range of equipment ranging from Internet of Figure 3 represents a good starting point, as it

28 MAY 2021 | www.powerelectronicsnews.com MAY 2021 | www.powerelectronicsnews.com 29