Page 15 - EETEurope FlipBook February

P. 15

EE|Times EUROPE 15

Industrial Computing Moves to the Mission-Critical Edge

heterogeneous, interconnected, virtualized

set of computing resources, which can host

the applications where needed and when

needed. These will be deployed in the form

of virtual machines and containers orches-

trated from the cloud or locally.

Let’s discuss a specific use case at an Audi

manufacturing plant, more specifically for

the Audi A3. Audi’s plant in Neckarsulm,

Germany, has 2,500 autonomous robots on its

production line. Each robot is equipped with a

tool of some kind, from glue guns to screw-

drivers, and performs a specific task required

to assemble an Audi automobile.

Audi assembles up to approximately 1,000

vehicles every day at the Neckarsulm factory,

and there are 5,000 welds in each car. To

ensure the quality of its welds, Audi performs

manual quality-control inspections. It is

impossible to inspect 1,000 cars every day

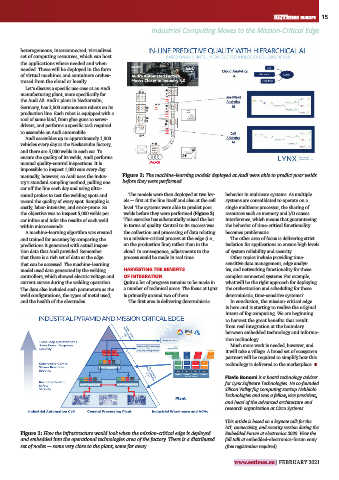

manually, however, so Audi uses the indus- Figure 3: The machine-learning models deployed at Audi were able to predict poor welds

try’s standard sampling method, pulling one before they were performed.

car off the line each day and using ultra-

sound probes to test the welding spots and The models were then deployed at two lev- behavior in multicore systems. As multiple

record the quality of every spot. Sampling is els — first at the line itself and also at the cell systems are consolidated to operate on a

costly, labor-intensive, and error-prone. So level. The systems were able to predict poor single multicore processor, the sharing of

the objective was to inspect 5,000 welds per welds before they were performed (Figure 3). resources such as memory and I/O causes

car inline and infer the results of each weld This exercise has substantially raised the bar interference, which means that guaranteeing

within microseconds. in terms of quality. Central to its success was the behavior of time-critical functionality

A machine-learning algorithm was created the collection and processing of data relating becomes problematic.

and trained for accuracy by comparing the to a mission-critical process at the edge (i.e., The other area of focus is delivering strict

predictions it generated with actual inspec- on the production line) rather than in the isolation for applications to ensure high levels

tion data that Audi provided. Remember cloud. In consequence, adjustments to the of system reliability and security.

that there is a rich set of data at the edge process could be made in real time. Other topics include providing time-

that can be accessed. The machine-learning sensitive data management, edge analyt-

model used data generated by the welding HARVESTING THE BENEFITS ics, and networking functionality for these

controllers, which showed electric voltage and OF INTEGRATION complex connected systems. For example,

current curves during the welding operation. Quite a lot of progress remains to be made in what will be the right approach for deploying

The data also included such parameters as the a number of technical areas. The focus at Lynx the orchestration and scheduling for these

weld configurations, the types of metal used, is primarily around two of them. deterministic, time-sensitive systems?

and the health of the electrodes. The first area is delivering deterministic In conclusion, the mission-critical edge

is here and is starting to realize the original

intent of fog computing. We are beginning

to harvest the great benefits that result

from real integration at the boundary

between embedded technology and informa-

tion technology.

Much more work is needed, however, and

it will take a village. A broad set of ecosystem

partners will be required to simplify how this

technology is delivered to the marketplace. ■

Flavio Bonomi is a board technology adviser

for Lynx Software Technologies. He co-founded

Silicon Valley fog computing startup Nebbiolo

Technologies and was a fellow, vice president,

and head of the advanced architecture and

research organization at Cisco Systems.

This article is based on a keynote talk for the

IoT, connectivity, and security session during the

Figure 2: How the infrastructure would look when the mission-critical edge is deployed Embedded Forum at electronica 2020. View the

and embedded into the operational technologies area of the factory. There is a distributed full talk at embedded-electronics-forum.com/

set of nodes — some very close to the plant, some far away. (free registration required).

www.eetimes.eu | FEBRUARY 2021