Page 16 - PEN eBook July 2022

P. 16

Thermal Management Thermal Management

For further improved Z and

thja

dynamic power dissipation for

TSC, the implementation of an

intermediate heat spreader is

a good option, as shown in

Figure 7. The thermal capacity

of this additional heatsink

can store for a certain time

(some seconds) the additional

heat and transfer it further Figure 7: Single-device heat-spreader mounting

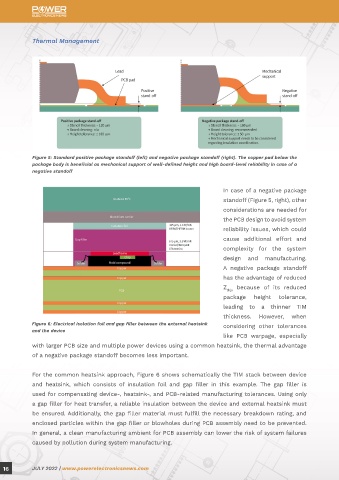

Figure 5: Standard positive package standoff (left) and negative package standoff (right). The copper pad below the

package body is beneficial as mechanical support of well-defined height and high board-level reliability in case of a to the common heatsink

negative standoff and ambience. Depending on the system design, removing the common heatsink and TIM is also

possible for improved system Z , wherein the heat spreader is the primary heatsink and is directly

thja

In case of a negative package cooled by the fan airflow.

standoff (Figure 5, right), other

considerations are needed for

the PCB design to avoid system

reliability issues, which could

cause additional effort and

complexity for the system

design and manufacturing.

A negative package standoff

has the advantage of reduced

Z because of its reduced

thja

package height tolerance,

leading to a thinner TIM

thickness. However, when

Figure 6: Electrical isolation foil and gap filler between the external heatsink considering other tolerances

and the device

like PCB warpage, especially

with larger PCB size and multiple power devices using a common heatsink, the thermal advantage

of a negative package standoff becomes less important. Figure 8: Typical transient thermal impedance junction ambient (Z thja ) for multiple packages at forced convection

For the common heatsink approach, Figure 6 shows schematically the TIM stack between device

and heatsink, which consists of insulation foil and gap filler in this example. The gap filler is Thermal performance

used for compensating device-, heatsink-, and PCB-related manufacturing tolerances. Using only Figure 8 shows Z time-dependent plots for selected through-hole device (THD), BSC SMD,

thja

a gap filler for heat transfer, a reliable insulation between the device and external heatsink must and TSC SMD packages considering an FR4-based PCB design with forced air cooling. The same

be ensured. Additionally, the gap filler material must fulfill the necessary breakdown rating, and device inside all shown packages is assumed just as the same power losses. Comparing DDPAK

enclosed particles within the gap filler or blowholes during PCB assembly need to be prevented. (TSC package) with TO263 (BSC package) on an FR4-based PCB, DDPAK achieves 60% lower Z ,

thja

In general, a clean manufacturing ambient for PCB assembly can lower the risk of system failures although the effective cooling area of both packages is quite similar. DDPAK bypasses the bottleneck

caused by pollution during system manufacturing. “thermal vias,” as described in the section before. The graph also illustrates that top-side packages

16 JULY 2022 | www.powerelectronicsnews.com JULY 2022 | www.powerelectronicsnews.com 17