Page 51 - PEN Ebook May 2021

P. 51

Design Design

The first is the high-temperature operating life AEC1, a 65V buck converter, is able to meet such

(HTOL) test that simulates operating conditions stringent reliability requirements while delivering

to provoke temperature- and voltage-related a 2A output.

fail mechanisms inside a testing chamber (see

Figure 2). The second is the temperature cycling

(TC) test, which stresses the IC for mechanical UNDERSTANDING THE

fail mechanisms, as the IC is made of different ACCELERATION FACTOR

materials that each have different temperature The HTOL test is defined by the JEDEC standard,

coefficients. JESD22-A108. A set of 231 units are subjected to

1,000 hours of operation time at 125°C. This test

These are just two of the qualification stresses uses the Arrhenius model to determine the ac-

that an IC must pass before it can be released. celeration factor (Af), which provides the needed

The whole set of qualification tests for automo- test time (tt) to simulate the equivalent time of

tive ICs are defined by the AEC-Q100 standards, real-world operation. Table 1 shows an exam-

and many of these tests are also specified in the ple with a mission profile that is 12,000 hours of

JEDEC standards. Some applications have even operation at an average junction temperature (T )

J

higher electronics reliability requirements, such of 87°C. T is the temperature of the silicon, and

J

as trucks and ruggedized vehicle systems, which it should be especially considered with ICs that

must be able to handle double the qualification have significant power dissipation, as the ambi-

stress for HTOL and TC tests to meet the target ent temperature (T ) would be much lower than T .

J

A

Mission Profile requirements. MPS’s MPQ4572-

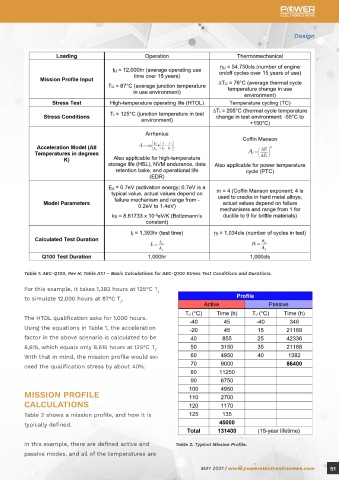

Table 1: AEC-Q100, Rev H; Table A7.1 – Basic Calculations for AEC-Q100 Stress Test Conditions and Durations.

For this example, it takes 1,393 hours at 125°C T

J

to simulate 12,000 hours at 87°C T .

J

The HTOL qualification asks for 1,000 hours.

Using the equations in Table 1, the acceleration

factor in the above scenario is calculated to be

8,615, which equals only 8,615 hours at 125°C T .

J

With that in mind, the mission profile would ex-

ceed the qualification stress by about 40%.

MISSION PROFILE

CALCULATIONS

Table 2 shows a mission profile, and how it is

typically defined.

In this example, there are defined active and Table 2: Typical Mission Profile.

Figure 2: MPS HTOL Chambers. passive modes, and all of the temperatures are

50 MAY 2021 | www.powerelectronicsnews.com MAY 2021 | www.powerelectronicsnews.com 51