Page 55 - PEN Ebook May 2021

P. 55

Design POWER MANAGEMENT

MISSION PROFILE DEFINITION CONCLUSION

Finally, who is actually required to make these Applications are being designed for increasing

calculations, and which party is responsible? For reliability requirements under multiple stress

automotive applications, the AEC-Q100 standard conditions. This is predominantly driven by the

provides clarity. In Appendix 7 of Rev. H there is a automotive industry and industrial application

flowchart that is applicable for the evaluation for requirements. Mission profiles are receiving in-

existing and qualified components (see Figure 4). creased attention, and are required to match the

target application’s real-life stressors as closely

At first, the mission profile for the electronic as possible. IC manufacturers must then design

control unit (ECU) is determined by the Tier 1, devices that can maintain their specified per-

which must be translated into the mission profile formance under that anticipated lifetime stress,

that the component would be subjected to. If the such as the MPQ8875A-AEC1 and MPQ4572-AEC1

component exists and has already been qualified, from MPS. It is always a good idea for Tier 1 de-

the basic calculation has already been done by signers and IC creators to team up early in the

the component manufacturer. process, and evaluate how the application can

be designed to best meet the real-life require-

Figure 1 shows the HTOL qualification that rep- ments relative to ECU reliability while maximizing

resents the basic mission profile outlined earlier cost-effectiveness.

in this article. With this data and the Arrhenius

model, the Tier 1 can determine whether or not How to Choose

the real-life application mission profile is com-

parable to the testing conditions. The same is the Right Power

true for mission profiles that refer to parameters

Management Strategy

other than temperature and voltage stress.

By Wilfried Dron, CEO of Wisebatt

Battery life is one of the core challenges in IoT. It performance gain, cost and form factor. Wilfried

relies on almost every specification of the de- Dron, CEO and cofounder at Wisebatt illustrates

vice (hardware and firmware architecture, size, these criteria through some of the most common

environment...). This is why power consumption power management strategies.

must be taken into consideration very early in the

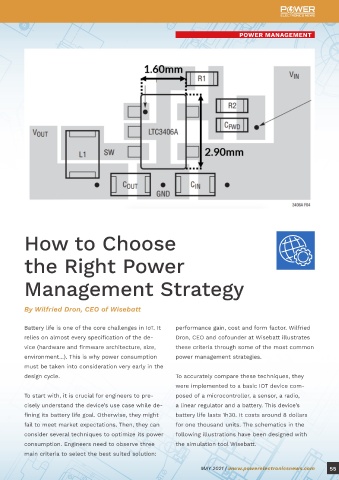

design cycle. To accurately compare these techniques, they

were implemented to a basic IOT device com-

For More Information To start with, it is crucial for engineers to pre- posed of a microcontroller, a sensor, a radio,

cisely understand the device’s use case while de- a linear regulator and a battery. This device’s

fining its battery life goal. Otherwise, they might battery life lasts 1h30. It costs around 8 dollars

▶ MPS’s MPQ4572-AEC1

fail to meet market expectations. Then, they can for one thousand units. The schematics in the

consider several techniques to optimize its power following illustrations have been designed with

▶ Monolithic Power Systems (MPS) consumption. Engineers need to observe three the simulation tool Wisebatt.

main criteria to select the best suited solution:

54 MAY 2021 | www.powerelectronicsnews.com MAY 2021 | www.powerelectronicsnews.com 55