Page 24 - PEN eBook October 2022

P. 24

SEMICONDUCTORS Semiconductors

Cordless vacuum cleaners with lithium-ion batteries are now popular, with useful run times and suction

power, but there is always commercial pressure to perform better. While battery technology improves

slowly, limited by the physics of chemical processes, there are opportunities with the motor to make

performance improvements using known technology.

Early DC motors used in cordless vacuum cleaners were of the “brushed” type and had the advantages

of simplicity of drive — just applying a voltage made them run up to their maximum speed. However,

brushes wear; produce sparks, noise, and vibration; and the best efficiency attainable is about 80%,

wasting battery energy and producing uncomfortable heat. Controlling speed means varying the voltage,

which reduces efficiency further.

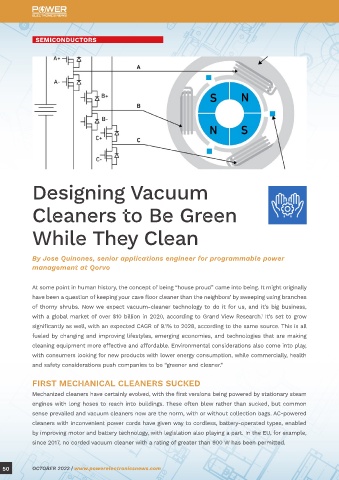

An alternative is the brushless DC (BLDC)

Designing Vacuum motor, which is longer-lasting, more efficient

(at up to about 96%), and much quieter

— a major consideration. There’s always a

Cleaners to Be Green downside, though, and that is that the BLDC

motor needs an AC drive, typically in three

While They Clean phases 120˚ apart for three stator windings,

with the initiation of each drive phase or

“commutation” triggered by the rotor angle.

By Jose Quinones, senior applications engineer for programmable power Rotational position is determined typically

management at Qorvo Figure 1: A brushless DC motor requires a three-phase AC by three Hall-effect sensors or by more

drive. (Source: Qorvo)

complex, sensorless methods that look

At some point in human history, the concept of being “house proud” came into being. It might originally at the voltage on the windings to derive

have been a question of keeping your cave floor cleaner than the neighbors’ by sweeping using branches position, when they are unenergized in the switching sequence. The current in the windings must also

of thorny shrubs. Now we expect vacuum-cleaner technology to do it for us, and it’s big business, be driven in alternate directions in the commutation sequence, so the most convenient arrangement

with a global market of over $10 billion in 2020, according to Grand View Research. It’s set to grow for the drive is a “bridge” of semiconductor switches, typically MOSFETS (Figure 1).

1

significantly as well, with an expected CAGR of 9.1% to 2028, according to the same source. This is all

fueled by changing and improving lifestyles, emerging economies, and technologies that are making Adding this type of electronic drive is more expensive, but this is offset by improvement in performance,

cleaning equipment more effective and affordable. Environmental considerations also come into play, not only in power and efficiency but also in controllability: The drive voltage applied during each phase

with consumers looking for new products with lower energy consumption, while commercially, health can be pulse-width–modulated (PWM) to keep speed constant under different load conditions and

and safety considerations push companies to be “greener and cleaner.” varied to suit the surface type. Costs are also mitigated by increased integration of the electronics

required into systems-on-chip (SoCs), which can include all the digital and analog interfaces required,

FIRST MECHANICAL CLEANERS SUCKED power rail management, PWM generation and control algorithms, and drivers for the power switches.

Mechanized cleaners have certainly evolved, with the first versions being powered by stationary steam Figure 2 shows the features included in a BLDC motor controller/driver SoC from Qorvo. 2

engines with long hoses to reach into buildings. These often blew rather than sucked, but common

sense prevailed and vacuum cleaners now are the norm, with or without collection bags. AC-powered HIGHEST-PERFORMANCE VACUUM CLEANERS USE

cleaners with inconvenient power cords have given way to cordless, battery-operated types, enabled PERMANENT-MAGNET SYNCHRONOUS MOTORS

by improving motor and battery technology, with legislation also playing a part. In the EU, for example, For really high-performance vacuum cleaners, a specific type of BLDC motor can be used: the

since 2017, no corded vacuum cleaner with a rating of greater than 900 W has been permitted. permanent-magnet synchronous motor (PMSM). This motor is more efficient than the BLDC type,

50 OCTOBER 2022 | www.powerelectronicsnews.com OCTOBER 2022 | www.powerelectronicsnews.com 51