Page 23 - PEN eBook October 2022

P. 23

Test & Measurement MOTOR CONTROL

▶ Digital I/Os to enable ECU and other signal emulation

▶ Analog I/Os to measure voltage, current, strain, or other physical variables involved in

battery testing

The hardware abstraction layer of the BTS allows different instrumentation to contribute to

the overall system. It is straightforward to swap in/out items of test hardware when required,

irrespective of the vendor or the models, without further modification of the test system being

called for. Aliases enable this swapping while eliminating the need to alter test scripts or remap

the test software, which would otherwise prove time-consuming.

Pre-programmed test steps and use-case examples mean that it is not necessary to start the Brushed DC Motor

test setup from scratch. Implementation can therefore be completed much more quickly. NI has

successfully built up, and continues to expand, the ecosystem of partners who can assist here. Programmable Speed

These can work with customers to configure solutions so that they are fully optimized for specific

application criteria. Regulator

CONCLUSION

The automotive sector has to migrate away from a siloed approach whereby data is derived from test By Nazar Sliunchenko, technical documentation manager at Renesas

systems that lack compatibility with another and are consequently isolated. Instead, they need an Electronics

open and fully connected platform that can encompass all their test assets. This must also be both

scalable and upgradeable. By adopting NI’s BTS and using it to orchestrate test operations, automakers This article describes how to design and build a low-noise, high-performance, low-cost brushed

will have a single point of contact via which all the battery tests they are conducting may be routed, DC motor programmable speed regulator. The regulator is immune to the temperature, voltage, and

interfacing with facilities in numerous geographic locations. This will allow them to shorten the time motor load variation. Also, this circuit is not sensitive to the motor coil resistance, which allows

and engineering effort that goes into the commissioning and configuration of test systems. It will also using different motors in the same application without any adjustments.

bring major advantages when it comes to ramping up their test activities as customer demand grows.

The described circuit is designed specifically

for devices in which a low-power brushed DC

motor is used and in which the stability of

the motor speed and low noise are critical.

The motor speed is pre-programmed and does

not require trimming after assembly, though it

is possible to reprogram it to a different speed

via I C.

2

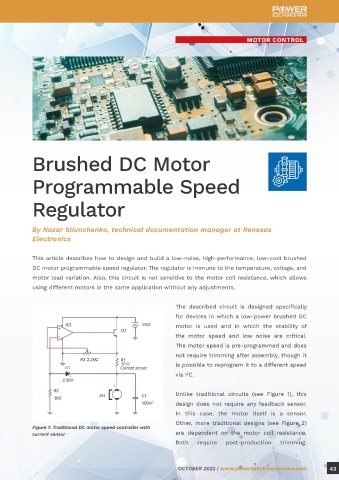

Unlike traditional circuits (see Figure 1), this

design does not require any feedback sensor.

In this case, the motor itself is a sensor.

Other, more traditional designs (see Figure 2)

Figure 1: Traditional DC motor speed controller with

current sensor are dependent on the motor coil resistance.

Both require post-production trimming.

42 OCTOBER 2022 | www.powerelectronicsnews.com OCTOBER 2022 | www.powerelectronicsnews.com 43