Page 28 - PEN eBook May 2023

P. 28

SEMICONDUCTORS SEMICONDUCTORS

implemented today with Si-based solutions. requirements for high efficiency and excellent thermal produced in energy-distribution systems. The

As SiC manufacturing costs improve, SiC-based 2-kV management, low EMI, good controllability and high employment of suitable active or passive filters is

boost solutions will offer significantly better system reliability. Like the energy infrastructure segment, SiC one of the classic methods for removing harmonic

costs. Being vertically integrated, onsemi has both the would provide a better value proposition for motor distortion in energy-distribution systems. By integrating

technical and supply chain capability to be a major control applications compared with Si IGBTs. For the harmonic compensation function directly into the

player in this space.” example, in the case of servo drives, for a similar-sized converter and doing away with the need for special

die current rating, pulse current rating would be higher, filters, power devices based on SiC can operate at very

WHAT’S NEXT? resulting in passive cooling solutions and the possibility high switching voltages and frequencies, which reduces

There are several more applications, besides to integrate the drive system with the motor itself. the size, complexity and cost of the design.

solar and EV chargers, in which SiC-based devices Given that more than 90% of the operation is under

compete, particularly 650-V–rated devices. constant speed or low torque operation, conduction Although SiC’s characteristics have been known

loss improvement is significant with SiC. Several for some time, the first SiC power devices were just

According to Sattu, one such example is in data other emerging applications, such as solid-state recently produced, beginning in the early 2000s with

center power supplies. “With the new 80 Plus circuit breakers, solid-state transformers and fuel-cell the use of 100-mm wafers. Most manufacturers

titanium requirements and light-load efficiency inverters, also benefit from similar high efficiency and switched over to 150-mm wafers a few years ago and,

requirements, there is a system-level shift in how thermal benefits offered with the EliteSiC portfolio.” recently, although still in the research stage,

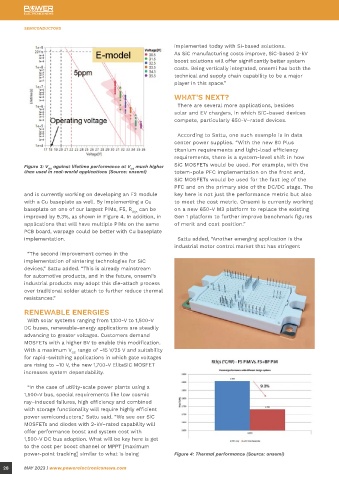

Figure 3: V against lifetime performance at V much higher SiC MOSFETs would be used. For example, with the large-scale manufacturing of 200-mm (8-inch) wafers.

GS

GS

than used in real-world applications (Source: onsemi) totem-pole PFC implementation on the front end, For e-mobility and renewable-energy systems, power

SiC MOSFETs would be used for the fast leg of the management solutions must provide performance SiC wafers’ shift from 4 to 6 inches didn’t go well

PFC and on the primary side of the DC/DC stage. The improvements, cost savings and quicker development due to the challenge of keeping the same quality and

and is currently working on developing an F2 module key here is not just the performance metric but also times. A SiC stack approach that improves performance yield. The material’s properties present the biggest

with a Cu baseplate as well. By implementing a Cu to meet the cost metric. Onsemi is currently working and lowers prices is currently very advantageous for problem for SiC manufacture. SiC takes more energy,

baseplate on one of our largest PIMs, F5, R thjs can be on a new 650-V M3 platform to replace the existing designers of EVs, commercial transportation, renewable longer and higher temperatures for crystal formation

improved by 9.3%, as shown in Figure 4. In addition, in Gen 1 platform to further improve benchmark figures energy and storage systems. and processing due to its extreme hardness (nearly

applications that will have multiple PIMs on the same of merit and cost position.” diamond-like). Additionally, because of its great

PCB board, warpage could be better with Cu baseplate SiC devices are widely used in the automobile transparency and high refractive index, the most

implementation. Sattu added, “Another emerging application is the industry, notably in the manufacture of EVs and plug-in common crystalline structure (4H-SiC) makes it

industrial motor control market that has stringent hybrid vehicles. The power systems for next-generation challenging to analyze the material for surface flaws

“The second improvement comes in the EVs must be able to boost the vehicle’s efficiency that can possibly influence epitaxial growth or final

implementation of sintering technologies for SiC (leading to an improvement in range) and the rate of component yield.

devices,” Sattu added. “This is already mainstream battery recharging.

for automotive products, and in the future, onsemi’s Crystalline stacking faults, surface particles,

industrial products may adopt this die-attach process SiC inverters are proven to be a crucial component micropipes, pits, scratches and stains are the principal

over traditional solder attach to further reduce thermal of the answer to these problems. An inverter based flaws that might appear while making SiC substrates.

resistances.” on SiC can achieve up to 99% efficiency, compared On 150-mm wafers rather than 100-mm wafers,

with a standard inverter’s 97% to 98% efficiency in these variables, which might negatively influence the

RENEWABLE ENERGIES transferring energy from the battery to the motor. It is performance of SiC devices, have been seen more

With solar systems ranging from 1,100-V to 1,500-V crucial to emphasize how a one- or two-decimal–place frequently. SiC’s manufacture presents difficult hurdles

DC buses, renewable-energy applications are steadily boost in efficiency has a big positive impact on the in terms of cycle time, cost and dicing performance,

advancing to greater voltages. Customers demand overall vehicle. as it is the third-hardest composite material in the

MOSFETs with a higher BV to enable this modification. world and also exceedingly delicate. Automotive and

With a maximum V range of –15 V/25 V and suitability Microgrids have become more important in the industrial markets will significantly benefit from the

GS

for rapid-switching applications in which gate voltages effort to reduce greenhouse gas emissions and the switch to 200-mm SiC wafers as they quicken the

are rising to –10 V, the new 1,700-V EliteSiC MOSFET amount of energy obtained from fossil fuels due to process of electrifying their systems and goods. As

increases system dependability. the rising demand for energy and the expanding usage product volumes increase, it is critical for promoting

of renewable-energy sources. However, the microgrid economies of scale.

“In the case of utility-scale power plants using a system cannot employ Si-based solid-state inverters

1,500-V bus, special requirements like low cosmic and switches because they are too big and ineffective.

ray–induced failures, high efficiency and combined Due to their greater BV and switching frequency, WBG

with storage functionality will require highly efficient semiconductors like SiC are positioning themselves

power semiconductors,” Sattu said. “We see our SiC as a key element in the development of effective and

MOSFETs and diodes with 2-kV–rated capability will dependable microgrids.

offer performance boost and system cost with

1,500-V DC bus adoption. What will be key here is get Due to the non-sinusoidal currents pulled from

to the cost per boost channel or MPPT [maximum the numerous electronic devices connected to the

power-point tracking] similar to what is being Figure 4: Thermal performance (Source: onsemi) network, there is a significant quantity of harmonics

28 MAY 2023 | www.powerelectronicsnews.com MAY 2023 | www.powerelectronicsnews.com 29