Page 23 - PEN_Ebook_October2021

P. 23

MOTOR CONTROL Motor Control

TWO-LEVEL INVERTER TOPOLOGY AND MOTOR CONTROL

BASICS

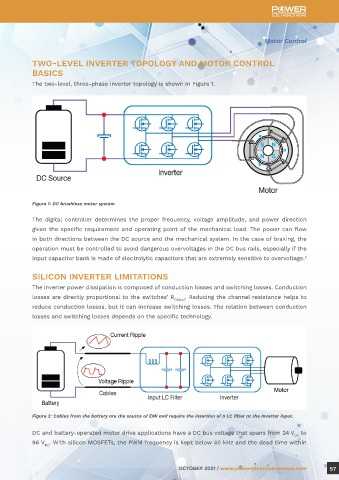

The two-level, three-phase inverter topology is shown in Figure 1.

Figure 1: DC brushless motor system

The digital controller determines the proper frequency, voltage amplitude, and power direction

given the specific requirement and operating point of the mechanical load. The power can flow

in both directions between the DC source and the mechanical system. In the case of braking, the

operation must be controlled to avoid dangerous overvoltages in the DC bus rails, especially if the

input capacitor bank is made of electrolytic capacitors that are extremely sensitive to overvoltage. 3

GaN Devices for Motor SILICON INVERTER LIMITATIONS

The inverter power dissipation is composed of conduction losses and switching losses. Conduction

Drive Applications losses are directly proportional to the switches’ R DS(on) . Reducing the channel resistance helps to

reduce conduction losses, but it can increase switching losses. The relation between conduction

losses and switching losses depends on the specific technology.

By Marco Palma, director of motor drive systems and applications at Efficient

Power Conversion

Today, the permanent magnet motor, also known as the DC brushless motor, is widely used and

offers higher torque capability per cubic inch and higher dynamics when compared with other

motors. So far, silicon-based power devices have been dominant in inverter electronics, but today,

their performance is nearing their theoretical limits. There is an increasing need for higher power

1,2

density. Gallium nitride transistors and ICs have the best attributes to satisfy these needs.

GaN’s superior switching behavior helps to remove dead time and increase PWM frequency to Figure 2: Cables from the battery are the source of EMI and require the insertion of a LC filter at the inverter input.

obtain unmatched sinusoidal voltage and current waveforms for smoother, silent operation with

higher system efficiency. Power density increases with the substitution of electrolytic capacitors in DC and battery-operated motor drive applications have a DC bus voltage that spans from 24 V to

DC

the input filter with smaller, cheaper, and more reliable ceramic capacitors. 96 V . With silicon MOSFETs, the PWM frequency is kept below 40 kHz and the dead time within

DC

56 OCTOBER 2021 | www.powerelectronicsnews.com OCTOBER 2021 | www.powerelectronicsnews.com 57