Page 54 - EE Times Europe Magazine | April2019

P. 54

54 EE|Times EUROPE — Boards & Solutions Insert

Thermal and Vibration Energy Powers IoT Devices

Design considerations for thermoelec-

tric-energy–harvesting systems “include

electrical and thermal requirements, ther-

moelectric materials, application-specific

considerations, durability targets, selling price,

and engineering budget,” said Piggott.

Vibrations are a ubiquitous energy source.

Every car on the road creates vibrations on the

asphalt and in the cab. Given the number of

cars on the world’s motorways, the appeal of

Figure 2: Equivalent circuit of piezoelectric effect (Image: “A piezoelectric vibration based gener- deriving energy from vibrations is clear.

ator for wireless electronics.” Smart Materials and Structures 13 (2004) 1131–1142) Maxim Integrated’s MAX17710 PMIC is a

complete system for charging and protecting

micropower-storage cells and can manage

Figure 3: poorly regulated sources such as energy-

Simplified operat- harvesting devices with output levels ranging

ing circuit of the from 1 µW to 100 mW (Figure 3).

MAX17710 The AEM30940 integrated energy man-

(Image: Maxim agement subsystem from e-peas extracts DC

Integrated) power from a TEG, piezo generator, micro-

turbine generator, or high-frequency RF

inputs to simultaneously store energy in a

rechargeable element and supply the system

with two independent regulated voltages. The

PMIC integrates an ultra-low-power boost

converter to charge a storage element, such as

a lithium-ion battery, a thin-film battery, or a

super- or conventional capacitor. It can start

operating with empty storage elements at an

input voltage as low as 380 mV and an input

power of just 3 µW (Figure 4).

The LTC3588-1 integrated circuit shown

in Figure 5 offers a complete energy storage

solution, optimized for high-impedance

generators such as piezoelectric transducers.

The Analog Devices circuit features a low-

loss full-wave rectifier and a high-efficiency

synchronous buck converter that transfers

energy from a storage device at the input to a

regulated voltage output capable of supplying

loads up to 100 mA. It is available in a

3 × 3-mm DFN or 10-conductor MSE package.

To design a fully autonomous wireless

sensor system effectively, you need low-

power-consumption microcontrollers and

transducers that consume a minimum amount

of electricity using low-energy environments.

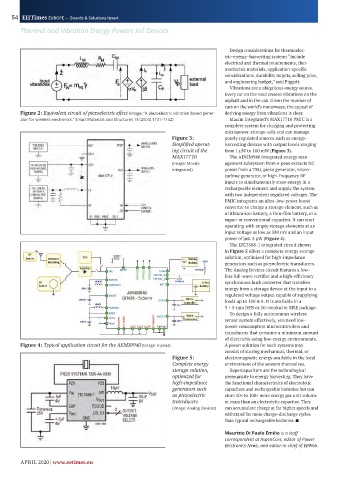

Figure 4: Typical application circuit for the AEM30940 (Image: e-peas) A power solution for such systems may

consist of storing mechanical, thermal, or

Figure 5: electromagnetic energy available in the local

Complete energy environment of the sensors themselves.

storage solution, Supercapacitors are the technological

optimized for prerequisite to energy harvesting. They have

high-impedance the functional characteristics of electrolytic

generators such capacitors and rechargeable batteries but can

as piezoelectric store 10× to 100× more energy per unit volume

transducers or mass than an electrolytic capacitor. They

(Image: Analog Devices) can accumulate charge at far higher speeds and

withstand far more charge-discharge cycles

than typical rechargeable batteries. ■

Maurizio Di Paolo Emilio is a staff

correspondent at AspenCore, editor of Power

Electronics News, and editor-in-chief of EEWeb.

APRIL 2020 | www.eetimes.eu