Page 33 - PEN eBook February 2024

P. 33

TEST & MEASUREMENT TEST & MEASUREMENT

Figure 1: V-cycle development flow

software and hardware design, model- and software- BIL REAL-TIME SIMULATION

CATARC Enhances in-the-loop verification, HIL testing and real-vehicle PLATFORM

testing. Notably, HIL testing of the controller plays

In response to these challenges, CATARC employs

a key role in this process. The HIL test platform

Battery Testing establishes a virtual operating environment for the simulation and testing to introduce a comprehensive

controller, verifying its functions by providing specific

set of BIL test solutions. This platform effectively

narrows the gap between HIL tests and real-vehicle

input signals and monitoring corresponding output

with Innovative BIL signals. road and field tests, minimizing the demands for field,

environment and vehicle requirements. A comparison

While the traditional signal-level HIL test is effective

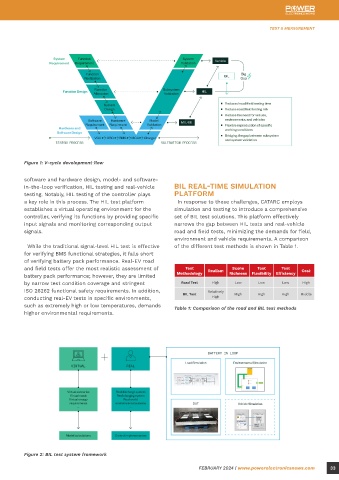

of the different test methods is shown in Table 1.

Simulation for verifying BMS functional strategies, it falls short Test Scene Test Test

of verifying battery pack performance. Real-EV road

and field tests offer the most realistic assessment of

battery pack performance; however, they are limited Methodology Realism Richness Flexibility Efficiency Cost

By Jian Ding and Kexin Yin, engineers in the electronic control department at CATARC by narrow test condition coverage and stringent Road Test High Low Low Low High

ISO 26262 functional safety requirements. In addition, Relatively

conducting real-EV tests in specific environments, BIL Test High High High High Middle

While traditional signal-level hardware-in-the-loop international standard improving the safety of electrical such as extremely high or low temperatures, demands Table 1: Comparison of the road and BIL test methods

(HIL) tests effectively verify battery management and electronic systems. higher environmental requirements.

system (BMS) functional strategies, they fail to validate

battery pack performance effectively. Real-vehicle GROWING COMPLEXITY OF BATTERY

road and field tests provide realistic insights, but their DESIGN

limitations in test condition coverage and stringent Across various countries, research on EVs consistently

requirements pose challenges. This case study explains identifies the battery as the most problematic

how the China Automotive Technology and Research component. Ensuring battery system safety involves

Center (CATARC) is pioneering advancements in battery considerations of battery-cell characteristics, module

testing by implementing a battery-in-the-loop (BIL) design, pack structure, exhaust design and the

simulation system. dominant role of the BMS. This system is increasingly

regarded as the core technology for EV makers, as

EVOLVING CHINESE AUTOMOTIVE evidenced by the surge in core intellectual-property

MARKET rights related to batteries.

The development of the automobile industry in China

is at a pivotal stage, presenting opportunities, risks and The typical approach in developing and testing EV

challenges. Electric vehicles hold substantial potential controllers involves adopting the V-cycle development

to enhance economic and industrial competitiveness, process, as shown in Figure 1. This process enhances

attracting investments in major markets. To address development efficiency, mitigates risks and reduces

functional safety concerns in automotive software, the overall workload. It efficiently progresses through

the industry has established ISO 26262, a critical system requirements, functional requirements, Figure 2: BIL test system framework

32 FEBRUARY 2024 | www.powerelectronicsnews.com FEBRUARY 2024 | www.powerelectronicsnews.com 33