Page 8 - PEN eBook October 2022

P. 8

Cover Story — Design Cover Story — Design

FLEXIBILITY AND CONFIGURABILITY IN A HIGHLY INTEGRATED The POSIF module performs time measurements between sensor event readings, error handling,

SOLUTION and synchronization with the PWM generation modules. This enhanced functionality allows the

CPU to run other tasks without having to implement specific firmware routines to enable these

readings, actions, and calculations. While it is a relatively simple implementation, there are some

disadvantages to a scheme that includes sensors, such as the increased cost of the sensors, the

high torque ripple, and the lower reliability (mechanical connectors and cables are coming out of

the motor).

SENSORLESS MOTOR CONTROL APPLICATIONS

In order to overcome some of the limitations in applications that require sensors, sensorless

techniques can be implemented. One method operates by reading the back electromotive force

(back EMF) of the motor’s windings. Another solution is a control scheme called field-oriented

control (FOC). Some of the advantages of this implementation are described as follows:

▶ Rotor position detection sensors are not required; a software estimator is used to calculate

rotor position and speed.

▶ The torque ripple is lower (compared with trapezoidal control), which translates into lower

power losses and audible noise reduction.

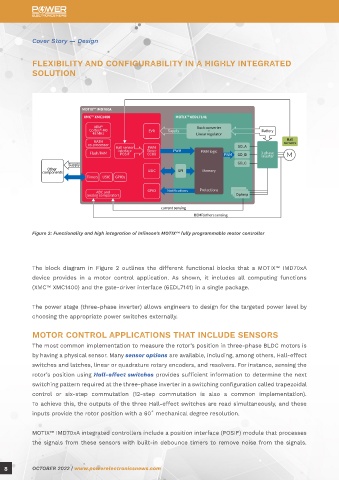

Figure 2: Functionality and high integration of Infineon’s MOTIX™ fully programmable motor controller

▶ Better torque control compared with trapezoidal control.

▶ Efficiency is higher throughout the speed range.

▶ High-resolution rotor angle/speed detection.

The block diagram in Figure 2 outlines the different functional blocks that a MOTIX™ IMD70xA ▶ Good dynamic load change response.

device provides in a motor control application. As shown, it includes all computing functions

(XMC™ XMC1400) and the gate-driver interface (6EDL7141) in a single package. On the other hand, one of the disadvantages of the FOC control scheme is its complexity;

consequently, the CPU requires more computing power. IMD70xA integrated controllers

The power stage (three-phase inverter) allows engineers to design for the targeted power level by include several peripherals that facilitate the implementation of FOC, such as a MATH

choosing the appropriate power switches externally. co-processor to perform calculations required in sensorless FOC algorithms to enable higher system

performance:

MOTOR CONTROL APPLICATIONS THAT INCLUDE SENSORS

The most common implementation to measure the rotor’s position in three-phase BLDC motors is ▶ MATH co-processor running at 96 MHz featuring:

by having a physical sensor. Many sensor options are available, including, among others, Hall-effect → 32-bit divider unit (DIV) for signed and unsigned division functions

switches and latches, linear or quadrature rotary encoders, and resolvers. For instance, sensing the → 24-bit coordinate rotation digital computer (CORDIC for trigonometric, linear, and

rotor’s position using Hall-effect switches provides sufficient information to determine the next hyperbolic functions

switching pattern required at the three-phase inverter in a switching configuration called trapezoidal

control or six-step commutation (12-step commutation is also a common implementation). ADDITIONAL FEATURES AND ADVANCED GATE-DRIVER

To achieve this, the outputs of the three Hall-effect switches are read simultaneously, and these FUNCTIONALITY

inputs provide the rotor position with a 60˚ mechanical degree resolution. Another essential aspect of IMD70xA integrated controllers is the addition of on-board power supplies

(synchronous buck converter and linear LDO). These provide power to the gate-driver charge pumps as

MOTIX™ IMD70xA integrated controllers include a position interface (POSIF) module that processes well as supply for the MCU and other external components like Hall-effect sensors, if used (Figure 3).

the signals from these sensors with built-in debounce timers to remove noise from the signals.

8 OCTOBER 2022 | www.powerelectronicsnews.com OCTOBER 2022 | www.powerelectronicsnews.com 9