Page 37 - EE Times Europe Magazine – November 2023

P. 37

EE|Times EUROPE 37

What’s Happening in the World of Micro-Energy Harvesting?

BEST EH TECHNOLOGIES FOR POWERING

IoT DEVICES

The micro-energy–harvesting technolo-

gies best suited to powering IoT devices

are photovoltaic (PV) cells; piezoelectric or

electrostatic converters, which harvest energy

from vibration; and Peltier thermoelectric

harvesters, which convert temperature gradi-

ents into electrical energy.

The power density of these sources ranges

from about 100 mW/cm for outdoor solar

2

to 10 mW/cm for a thermoelectric gener-

2

ator (TEG). The electrical characteristics

of the different harvesters vary widely. For

example, TEGs have low-impedance outputs,

producing continuous DC at a low voltage.

PV cells are similar, but the current, and

hence the impedance, varies with the level

of incident light. Piezoelectric harvesters

deliver shorter bursts of energy and usually Designed to help engineers quickly evaluate energy from several harvesting sources, the

at higher voltages than their TEG and PV demonstration platform shown comprises two PV harvesters, a piezoelectric harvester

counterparts. with a DC motor to generate vibration for it, two TEGs, and a heater and heatsinks to

This has led EH PMIC manufacturers to excite the TEGs.

offer a range of power management chips,

each designed to work with a particular there could be a lot of ambient vibration. In a System-level considerations come into

type of harvester. Some of these may also greenhouse, which may use smart, connected play, too. If wireless sensor modules are

need external components for impedance temperature and humidity sensors, the deployed close to hubs or routers, low-

transformation between the harvester and opposite is true. power, short-range radio protocols like

the chip. Bluetooth, Zigbee, Z-Wave or Wi-Fi can be

This presents a dilemma for the IoT device GAUGING HOW MUCH ENERGY used. The final selection is determined by

manufacturer. A slightly different device NEEDS TO BE HARVESTED the required data rate and signal range and

must be designed for each type of harvester. The nature of the end application, including costs. Where IoT devices are connected to a

Even then, there’s still the problem that the the wireless connectivity protocol or proto- network that spans a wide geographic area,

kinds of energy sources available to power cols used by IoT devices, are key determinants cellular or LPWAN connections may be the

the IoT device may not be known at the time of power consumption. For example, smart only options, both of which are power-

it’s being designed. For example, there’s not meters send tiny data packets infrequently, hungry compared with short-range systems,

much opportunity for solar PV in a railway whereas streaming video from security as the comparison table shows.

tunnel or inside an industrial plant, but cameras is data- and power-hungry. A detailed analysis of the power profile of

an IoT device when it’s deployed in the field is

the first step in determining the performance

required from an energy-harvesting system.

EH PMICs EVOLVE TO SIMPLIFY

MICRO-ENERGY HARVESTING

While IoT could be designed with multiple EH

PMICs to create a range of inputs, each suited

to a particular type of harvester, this adds

cost and wastes hardware resources in most

applications.

The most recent trend is toward smarter,

multiple-input EH PMICs. With these, two or

more types of harvesters can be connected to

the same power management chip.

Micro-energy harvesting has not yet

delivered on the promise of a battery-less

world for IoT devices, but it is certainly on

the cusp of doing so. As costs fall,

energy-harvesting systems become simpler

to design and use, and electronic engineers

show more commitment toward environ-

mental responsibility. ■

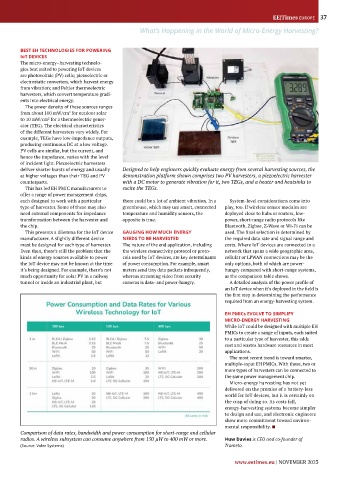

Comparison of data rates, bandwidth and power consumption for short-range and cellular

radios. A wireless subsystem can consume anywhere from 150 µW to 400 mW or more. Huw Davies is CEO and co-founder of

(Source: Voler Systems) Trameto.

www.eetimes.eu | NOVEMBER 2023