Page 33 - EE Times Europe Magazine – November 2023

P. 33

EE|Times EUROPE 33

Tapping AI for Leaner, Greener Semiconductor Fab Operations

consumption. Reducing the batch count can

lead to increased overall manufacturing effi-

ciency. Fewer batch changeovers and setups

mean less downtime, faster processing and

potentially higher throughput. This implies

reduced energy consumption, less equipment

usage and shorter production cycles, lowering

carbon emissions in the process.

As Potter pointed out, “In semiconductor

manufacturing, the relationship between

production volume and environmental impact

is not strictly linear. Adding one more wafer

does not proportionally increase the carbon

and resource footprint. A significant portion

of this impact remains relatively fixed, regard-

less of production volume. The key insight

is that software solutions like ours enable

increased production without new equipment

investment, reducing the substantial carbon

footprint associated with equipment acquisi-

tion in the semiconductor industry.”

Although Flexciton’s primary goal is to

optimize the manufacturing process for

efficiency, the company has begun to inte-

grate energy reduction into the production

programming equation.

Potter highlighted a research collaboration

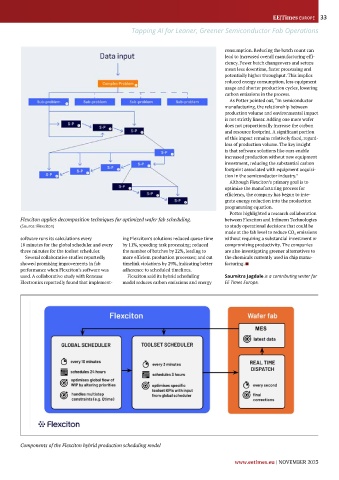

Flexciton applies decomposition techniques for optimized wafer fab scheduling. between Flexciton and Infineon Technologies

(Source: Flexciton) to study operational decisions that could be

made at the fab level to reduce CO 2 emissions

software runs its calculations every ing Flexciton’s solutions reduced queue time without requiring a substantial investment or

10 minutes for the global scheduler and every by 11%, speeding task processing; reduced compromising productivity. The companies

three minutes for the toolset scheduler. the number of batches by 22%, leading to are also investigating greener alternatives to

Several collaborative studies reportedly more efficient production processes; and cut the chemicals currently used in chip manu-

showed promising improvements in fab timelink violations by 29%, indicating better facturing. ■

performance when Flexciton’s software was adherence to scheduled timelines.

used. A collaborative study with Renesas Flexciton said its hybrid scheduling Saumitra Jagdale is a contributing writer for

Electronics reportedly found that implement- model reduces carbon emissions and energy EE Times Europe.

Components of the Flexciton hybrid production scheduling model

www.eetimes.eu | NOVEMBER 2023