Page 17 - EE Times Europe November 2021 final

P. 17

EE|Times EUROPE 17

How Preventive and Predictive Maintenance Is Changing Production

Gateways are used to collect and process the data from several smart the skilled technicians required to operate them. The data collected

sensor nodes or connect the nodes to the cloud. Edge processing can by the nodes is repeatable, reliable, and timely, and it can be analyzed

combine and distribute processing power among smart sensor nodes locally to trigger immediate decision-making, reduce power, and

and gateways. Doing so makes it possible to send the right data at the contribute to longer equipment life. Alternatively, under programmed

right time to enterprise-level systems for more advanced analyses. This conditions, the data can be transferred to the ST microcontrollers and

broadens the scope of anomaly detection and classification. microprocessors or to the cloud for deeper analysis.

Predictive maintenance is especially relevant for manufacturing, Therefore, although predictive maintenance’s requirement for more

food production plants, and the power and energy industry, wherein sensors on equipment increases the upfront costs in comparison with

prioritizing tasks to perform maintenance and repairs within the reactive or time-based preventive maintenance, it will be more eco-

shortest achievable time frame is critical. The objective is to prevent nomical in the long run, according to the U. S. Department of Energy

unplanned outages at the lowest possible operating costs. Operations and Maintenance study referenced earlier.

A wide range of smart sensor nodes are available from manufacturers

like STMicroelectronics (ST). Among these are environmental sensors CONCLUSION

for temperature, humidity, and pressure; inertial and motion sensors, As more factories implement preventive maintenance, the factories

including accelerometers, gyroscopes, inertial measurement units, that do not will quickly become less competitive. However, minimizing

and motion sensors; and ultrasound analog microphones. Smart the cost of preventive maintenance is a must for maximizing its ben-

sensor nodes containing these sensors can, for example, perform efits. For example, preventive maintenance software is a great tool for

vibration analysis ranging from simple pass/fail monitoring to high- creating an efficient maintenance schedule and helping managers make

accuracy, frequency-based data analysis. In addition, ST makes sure that resources are not spread too thinly on too many items at one

microelectromechanical-system sensors containing digital logic for time. In addition, prescriptive or customized maintenance, which uses

processing. The logic is optimized to run machine-learning algorithms advanced analytics, machine learning, and artificial intelligence to

that allow the developer to program the sensor so it can detect that the generate predictions about maintenance, can make recommendations

system sleeps unless the data it collects is appropriate to share with the to improve system operations. Finally, layering predictive maintenance

host processor, by exceeding a threshold or matching a pattern. onto prescriptive maintenance will produce a synergistic benefit. ■

Smart sensor nodes make good economic sense. Autonomous node

operations cost significantly less than portable piezoelectric probes and John Koon is a technology writer and an EE Times Europe contributor.

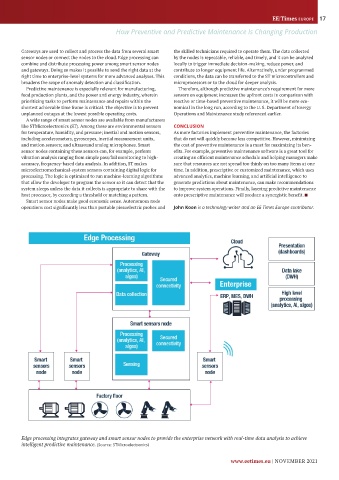

Edge processing integrates gateway and smart sensor nodes to provide the enterprise network with real-time data analysis to achieve

intelligent predictive maintenance. (Source: STMicroelectronics)

www.eetimes.eu | NOVEMBER 2021