Page 26 - EE Times Europe Magazine | February 2020

P. 26

24 EE|Times EUROPE

INDUSTRY 4.0

Designers Turning to MEMS

for Condition Monitoring of Power Devices

By Maurizio Di Paolo Emilio

s a fundamental tool to improve

production efficiency, condition

monitoring is accelerating the

A transition to Industry .0. It enables

continuous monitoring of electromechanical

equipment and power devices, facilitating

early detection and real-time diagnosis of

possible anomalies or failures. By identify-

ing and isolating potential problems before

they can compromise production, condition

monitoring makes it possible to optimize

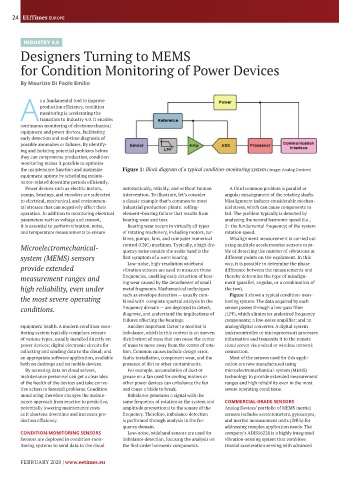

the maintenance function and maximize Figure 1: Block diagram of a typical condition-monitoring system (Image: Analog Devices)

equipment uptime by scheduling mainte-

nance-related downtime periods efficiently.

Power devices such as electric motors, automatically, reliably, and without human A third common problem is parallel or

pumps, bearings, and encoders are subjected intervention. To illustrate, let’s consider angular misalignment of the rotating shafts.

to electrical, mechanical, and environmen- a classic example that’s common to most Misalignment induces considerable mechan-

tal stresses that can negatively affect their industrial production plants rolling- ical stress, which can cause components to

operation. In addition to monitoring electrical element bearing failure that results from fail. The problem typically is detected by

parameters such as voltage and current, bearing wear and tear. analyzing the second harmonic speed (i.e.,

it is essential to perform vibration, noise, Bearing wear occurs in virtually all types 2 the fundamental frequency) of the system

and temperature measurements to ensure of rotating machinery, including motors, tur- rotation speed.

bines, pumps, fans, and computer numerical Misalignment measurement is carried out

Microelectromechanical- control (CNC) machines. Typically, a high-fre- using multiple accelerometer sensors capa-

ble of detecting the number of vibrations at

quency noise outside the audio band is the

system (MEMS) sensors first symptom of a worn bearing. different points on the equipment. In this

Low-noise, high-resolution wideband

provide extended vibration sensors are used to measure those way, it is possible to determine the phase

difference between the measurements and

measurement ranges and frequencies, enabling early detection of bear- thereby determine the type of misalign-

ment (parallel, angular, or a combination of

ing wear caused by the detachment of small

high reliability, even under metal fragments. Mathematical techniques the two).

Figure 1 shows a typical condition-mon-

the most severe operating such as envelope detection — usually com- itoring system. The data acquired by each

bined with complete spectral analysis in the

conditions. frequency domain — are deployed to detect, sensor passes through a low-pass filter

diagnose, and understand the implications of (LPF), which eliminates undesired frequency

failures affecting the bearings. components a low-noise amplifier and an

equipment health. A modern condition-mon- Another important factor to monitor is analog digital converter. A digital system

itoring system typically comprises sensors imbalance, which in this context is an uneven (microcontroller or microprocessor) processes

of various types, usually installed directly on distribution of mass that can cause the center information and transmits it to the remote

power devices; digital electronic circuits for of mass to move away from the center of rota- cloud server via a wired or wireless network

collecting and sending data to the cloud; and tion. Common causes include design error, connection.

an appropriate software application, available faulty installation, component wear, and the Most of the sensors used for this appli-

both on desktops and on mobile devices. presence of dirt or other contaminants. cation are now manufactured using

By accessing data on cloud servers, For example, accumulation of dust or microelectromechanical-system (MEMS)

maintenance personnel can get a clear idea grease on a fan used for cooling motors or technology to provide extended measurement

of the health of the devices and take correc- other power devices can unbalance the fan ranges and high reliability even in the most

tive action to forestall problems. Condition and cause a blade to break. severe operating conditions.

monitoring therefore changes the mainte- Imbalance generates a signal with the

nance approach from reactive to predictive, same frequency of rotation as the system and COMMERCIAL-GRADE SENSORS

potentially lowering maintenance costs amplitude proportional to the square of the Analog Devices’ portfolio of MEMS inertial

as it shortens downtime and increases pro- frequency. Therefore, imbalance detection sensors includes accelerometers, gyroscopes,

duction efficiency. is performed through analysis in the fre- and inertial measurement units (IMUs) for

quency domain. addressing complex application needs. The

CONDITION-MONITORING SENSORS Low-noise, wideband sensors are used for company’s ADIS1622 is a highly integrated

Sensors are deployed in condition-mon- imbalance detection, focusing the analysis on vibration-sensing system that combines

itoring systems to send data to the cloud the first-order harmonic components. triaxial acceleration sensing with advanced

FEBRUARY 2020 | www.eetimes.eu