Page 15 - PCIM and APEC 2021 - Technical Coverage, eBook

P. 15

APEC - Automotive APEC - ENERGY

EV TECHNOLOGY

The requirements in this sector are evolving rapidly, with power levels above 350 kW and efficiencies

of 95% becoming the “norm.” Key parameters in this market are compactness, robustness, and

increased reliability, which many companies are trying to solve with new technical solutions.

“It is essential to take advantage of SiC for its high switching speed in order to reduce the size of

various passive components,” said Husain. “With the increased efficiency and higher frequency of

SiC, it is easier to address thermal challenges while also achieving a small form factor.”

The new 1,200-V two-pack modules, based on planar technology and suitable for a drive voltage

in the range of 18–20 V, can be driven with negative gate voltages. The larger die reduces thermal

resistance compared with trench MOSFETs, thus lowering die temperature for the same operating

temperature. The NXH010P120MNF is a half-bridge in an F1 package, while the NXH006P120MNF2

is a 6-mΩ device in an F2 package. The pins are push-pull to help with assembly while also Megatrends in Energy

incorporating a negative temperature coefficient thermistor for temperature monitoring. Husain

also pointed out that the new modules can work with the NCD5700x, particularly the NCD57252, Storage

which offers 5-kV isolation for dual low-side, dual high-side, or half-bridge operation with typical

propagation delays of 60 ns.

By Maurizio Di Paolo Emilio, editor-in-chief of Power Electronics News and

European correspondent for EE Times

onsemi’s SiC technology also provides its 650-, 900-, and 1,200-V MOSFETs. The 650-V SiC MOSFETs

employ a new active-cell design combined with advanced thin-wafer technology that enables a

best-in-class figure of merit per (R × area). The 1,200-V and 900-V N-channel ones feature a Zero emissions is a target many

DS(on)

small chip size that reduces device capacitance and gate charge (Qg as low as 220 nC), reducing nations are willing to reach by 2050,

switching losses when operating at the high frequencies required by EV chargers. and investments have been allocated

for energy storage companies to

SiC offers a higher efficiency level than silicon, mainly due to significantly lower energy loss and reach this goal. During APEC, Peter

reverse charge. This leads to more switching power and less energy required in the switch-on and Wasmuth, co-founder and head of

switch-off phase. Lower heat loss also makes it possible to remove cooling systems, thus reducing Europe, Polarium, highlighted several

space, weight, and infrastructure cost. The high thermal conductivity of silicon carbide allows trends in energy storage.

better heat dissipation, offering smaller form factors than silicon. This allows cutting on lower costs

and having smaller packaging. Solar, wind, and other renewable

energy sources are set to grow

dramatically in the coming years, with

governments now aiming for net-zero

emissions. As distributed generation

For More Information becomes more widespread, the grid

will need to be increasingly flexible.

Storage systems can be the key

▶ Live Coverage of APEC 2021 tools to ensure this, as they allow

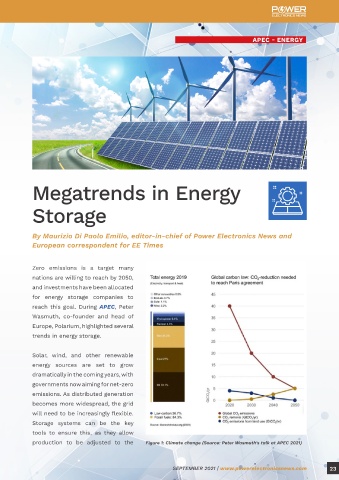

production to be adjusted to the Figure 1: Climate change (Source: Peter Wasmuth's talk at APEC 2021)

22 SEPTEMBER 2021 | www.powerelectronicsnews.com SEPTEMBER 2021 | www.powerelectronicsnews.com 23