Page 30 - EE Times Europe September 2021

P. 30

30 EE|Times EUROPE EE|Times EUROPE 30

30 EE|Times EUROPE

Enhancing Efficiency by Reducing Converter Stages and R in Power Management ICs

Embedding Security at the Edge ON

When this switching noise is introduced

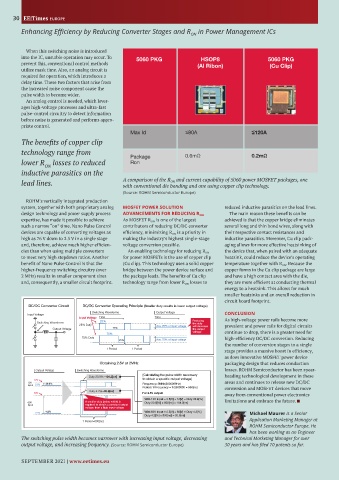

into the IC, unstable operation may occur. To 5060 PKG HSOP8 5060 PKG

prevent this, conventional control methods (Al Ribon) (Cu Clip)

utilize mask time. Also, an analog circuit is

required for operation, which introduces a

delay time. These two factors that arise from

the increased noise component cause the

pulse width to become wider.

An analog control is needed, which lever-

ages high-voltage processes and ultra-fast

pulse-control circuitry to detect information

before noise is generated and performs appro-

priate control.

Max Id ≤ 80A ≤ 120A

The benefits of copper clip

technology range from Package 0.6mΩ 0.2mΩ

lower R losses to reduced Ron

ON

inductive parasitics on the

lead lines. A comparison of the R ON and current capability of 5060 power MOSFET packages, one

with conventional die bonding and one using copper clip technology.

(Source: ROHM Semiconductor Europe)

ROHM’s vertically integrated production

system, together with both proprietary analog MOSFET POWER SOLUTION reduced inductive parasitics on the lead lines.

design technology and power supply process ADVANCEMENTS FOR REDUCING R ON The main reason these benefits can be

expertise, has made it possible to achieve As MOSFET R ON is one of the largest achieved is that the copper bridge eliminates

such a narrow “on” time. Nano Pulse Control contribu tors of reducing DC/DC converter several long and thin bond wires, along with

devices are capable of converting voltages as efficiency, minimizing R ON is a priority in their respective contact resistances and

high as 76 V down to 2.5 V in a single stage making the industry’s highest single-stage inductive parasitics. Moreover, Cu clip pack-

and, therefore, achieve much higher efficien- voltage conversion possible. aging allows for more effective heatsinking of

cies than when using multiple converters An enabling technology for reducing R ON the device that, when paired with an adequate

to meet very high stepdown ratios. Another for power MOSFETs is the use of copper clip heatsink, could reduce the device’s operating

benefit of Nano Pulse Control is that the (Cu clip). This technology uses a solid copper temperature together with R ON . Because the

higher-frequency switching circuitry (over bridge between the power device surface and copper forms in the Cu clip package are large

2 MHz) results in smaller component sizes the package leads. The benefits of Cu clip and have a high contact area with the die,

and, consequently, a smaller circuit footprint. technology range from lower R ON losses to they are more efficient at conducting thermal

energy to a heatsink. This allows for much

smaller heatsinks and an overall reduction in

circuit board footprint.

DC/DC Converter Circuit DC/DC Converter Operating Principle (Smaller duty results in lower output voltage)

Switching Waveforms Output Voltage

Input Voltage CONCLUSION

Input Voltage Time Time As high-voltage power rails become more

25% Reducing

Switching Waveforms the duty

25% Duty Ave. 25% of input voltage will decrease prevalent and power rails for digital circuits

Output Voltage 75% the output

voltage continue to drop, there is a greater need for

75%

75% Duty high-efficiency DC/DC conversion. Reducing

25% Ave. 75% of input voltage

the number of conversion stages to a single

1 Period 1 Period

stage provides a massive boost in efficiency,

as does innovative MOSFET power device

Obtaining 2.5V at 2MHz packaging design that reduces conduction

Output Voltage Switching Waveforms losses. ROHM Semiconductor has been spear-

[Calculating the pulse width necessary

Duty 20.8%=104.2[ns] heading technological development in these

12V to obtain a specific output voltage]

12V 20.8% Frequency: 2MHz(2000000Hz) areas and continues to release new DC/DC

Input 2.5V

Period: 1/Frequency = 1/2000000 = 500[ns] conversion and MOSFET devices that move

Duty 4.2%=20.8[ns]

60V For 2.5V output: away from conventional power electronics

With 12V Input = 2.5[V] + 12[V] = Duty 20.8[%]

60V A smaller duty (pulse width) is Duty 20.8[%] x 500[ns] = 104.2[ns] limitations and embrace the future. ■

Input required to obtain a constant output

voltage from a high input voltage

4.2% With 60V Input = 2.5[V] + 60[V] = Duty 4.2[%]

2.5V Michael Maurer is a Senior

Duty 4.2[%] x 500[ns] = 20.8[ns]

Application Marketing Manager at

1 Period=500[ns]

ROHM Semiconductor Europe. He

has been working as an Engineer

The switching pulse width becomes narrower with increasing input voltage, decreasing and Technical Marketing Manager for over

output voltage, and increasing frequency. (Source: ROHM Semiconductor Europe) 30 years and has filed 10 patents so far.

w

w

SEPTEMBER 2021 | www.eetimes.eu www.eetimes.eu | SEPTEMBER 2021

w

|

.eetimes.eu

1

2

2

SEPTEMBER

0