Page 37 - EE Times Europe Magazine | June2020

P. 37

EE|Times EUROPE 37

MOTOR CONTROL

Gate Driver Solutions Proliferate applications continue to strengthen, better

for Motor Control power conversion technology is also needed

to minimize total power losses and simplify

the design.

By Maurizio Di Paolo Emilio The driver is a basic element of BLDC

control. It is a power amplifier that produces

a voltage output to drive the high-current

lectric motors convert electrical according to the company. high-side and low-side IGBT gates of the

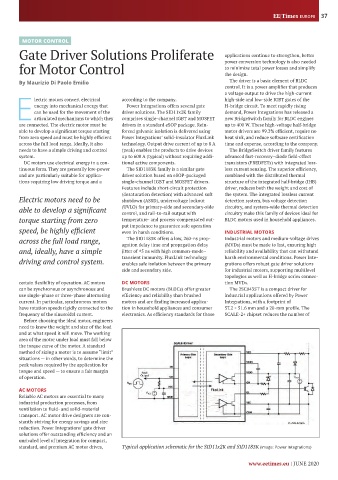

energy into mechanical energy that Power Integrations offers several gate H-bridge circuit. To meet rapidly rising

can be used for the movement of the driver solutions. The SID11x2K family demand, Power Integrations has released a

E articulated mechanisms to which they comprises single-channel IGBT and MOSFET new BridgeSwitch family for BLDC engines

are connected. The electric motor must be drivers in a standard eSOP package. Rein- up to 400 W. These high-voltage half-bridge

able to develop a significant torque starting forced galvanic isolation is delivered using motor drivers are 99.2% efficient, require no

from zero speed and must be highly efficient Power Integrations’ solid-insulator FluxLink heat sink, and reduce software certification

across the full load range. Ideally, it also technology. Output drive current of up to 8 A time and expense, according to the company.

needs to have a simple driving and control (peak) enables the products to drive devices The BridgeSwitch driver family features

system. up to 600 A (typical) without requiring addi- advanced fast-recovery–diode field-effect

DC motors use electrical energy in a con- tional active components. transistors (FREDFETs) with integrated loss-

tinuous form. They are generally low-power The SID1183K family is a similar gate less current sensing. The superior efficiency,

and are particularly suitable for applica- driver solution based on eSOP-packaged combined with the distributed thermal

tions requiring low driving torque and a single-channel IGBT and MOSFET drivers. structure of the integrated half-bridge (IHB)

Features include short-circuit protection driver, reduces both the weight and cost of

(desaturation detection) with advanced soft the system. The integrated lossless current

Electric motors need to be shutdown (ASSD), undervoltage lockout detection system, bus voltage detection

able to develop a significant (UVLO) for primary-side and secondary-side circuitry, and system-wide thermal detection

circuitry make this family of devices ideal for

control, and rail-to-rail output with

torque starting from zero temperature- and process-compensated out- BLDC motors used in household appliances.

speed, be highly efficient put impedance to guarantee safe operation INDUSTRIAL MOTORS

even in harsh conditions.

The SID1183K offers a low, 260-ns prop-

across the full load range, agation delay time and propagation delay Industrial motors and medium-voltage drives

(MVDs) must be made to last, ensuring high

and, ideally, have a simple jitter of ±5 ns with high common-mode– reliability and availability that can withstand

driving and control system. transient immunity. FluxLink technology harsh environmental conditions. Power Inte-

enables safe isolation between the primary

grations offers robust gate driver solutions

side and secondary side. for industrial motors, supporting multilevel

topologies as well as H-bridge series connec-

certain flexibility of operation. AC motors DC MOTORS tion MVDs.

can be synchronous or asynchronous and Brushless DC motors (BLDCs) offer greater The 2SC0435T is a compact driver for

use single-phase or three-phase alternating efficiency and reliability than brushed industrial applications offered by Power

current. In particular, synchronous motors motors and are finding increased applica- Integrations, with a footprint of

have rotation speeds rigidly connected to the tion in household appliances and consumer 57.2 × 51.6 mm and a 20-mm profile. The

frequency of the sinusoidal current. electronics. As efficiency standards for those SCALE-2+ chipset reduces the number of

Before choosing the ideal motor, engineers

need to know the weight and size of the load

and at what speed it will move. The working

area of the motor under load must fall below

the torque curve of the motor. A standard

method of sizing a motor is to assume “limit”

situations — in other words, to determine the

peak values required by the application for

torque and speed — to ensure a fair margin

of operation.

AC MOTORS

Reliable AC motors are essential to many

industrial production processes, from

ventilation to fluid- and solid-material

transport. AC motor drive designers are con-

stantly striving for energy savings and size

reduction. Power Integrations’ gate driver

solutions offer outstanding efficiency and an

unrivaled level of integration for compact,

standard, and premium AC motor drives, Typical application schematic for the SID11x2K and SID1183K (Image: Power Integrations)

www.eetimes.eu | JUNE 2020